22 Sep How to Select Complex Cable Assembly or Cable Harnesses Supplier

In the world of intricate electronics and advanced technological applications of interconnect solutions, comprehending the intricacies of a complex cable assembly or complex cable harness is pivotal.

Complex cable assemblies form the backbone of countless devices and systems, connecting the myriad electrical and data connections required for seamless operation. Understanding the intricacies of complex cable assemblies and harnesses is not only essential for ensuring optimal performance but also for choosing the right custom cable assembly manufacturer to meet your unique requirements.

In this article, we will delve into the essential aspects of complex cable assembly and cable harnesses, shedding light on their interrelation and complexity, while also providing you with tips to aid in your search for the perfect supplier to match your specific needs.

What Are Complex Cable Assemblies & Cable Harnesses?

First, what is a complex cable assembly? A cable assembly is one or more cables with connectors attached. Specifically, in its simplest form, a cable harness is a specified length of a certain cable type, such as fiber optic, with a connector attached at one or both ends.

A cable harness assembly is generally a grouping of various cable assemblies bound into one cable harness. Cable harnesses can include:

- fiber optic cable assemblies

- copper cable assemblies

- hybrid assemblies (fiber and copper)

- power cables

Most are custom harnesses and assemblies, so the level of complexity grows from there. They can run from the simplest assembly to extremely complex cable assembly designs.

Designing a Complex Cable Assembly or Cable Harness

The design and engineering of complex cable assemblies is a meticulous process, critical to the performance and functionality of various industrial systems and technological applications. To gain a deeper understanding of this intricate cable assembly design process, you can explore the detailed insights provided on NAI Group’s cable assembly design process page.

NAI Group is renowned for its expertise in designing and engineering cable assemblies, and their website offers valuable information on the subject. The design process typically begins with a comprehensive assessment of the specific requirements and objectives of the project. This involves determining the types of signals, power, and data that the cables will transmit, as well as the environmental conditions they will be exposed to.

Advanced CAD software and engineering tools are then employed to create detailed schematics and layouts, ensuring the precise placement of connectors, shielding, and other essential components. The design phase also considers factors like electrical performance, material selection, and compliance with industry standards, all with a focus on achieving optimal functionality, durability, and reliability.

For a comprehensive insight into the design and engineering of complex cable assemblies, speak with one of our cable harness experts.

What Makes A Cable Assembly Complex?

When it comes to interconnect solutions there are both cable assemblies and complex cable assemblies. What makes a cable assembly complex? Complex cable assemblies have more components, different types of cables, and connectors that set them apart from regular cable assemblies.

There are many copper cable types from which to select for a cable assembly:

- Hook-up wire

- 3 – UTP and STP

- 4 – UTP and STP

- Coaxial

- Multi-conductor

- Power

And, there are many fiber optic cable choices:

- Ribbon

- Single Mode

- Multimode

- Hybrid

- Simplex

- Duplex

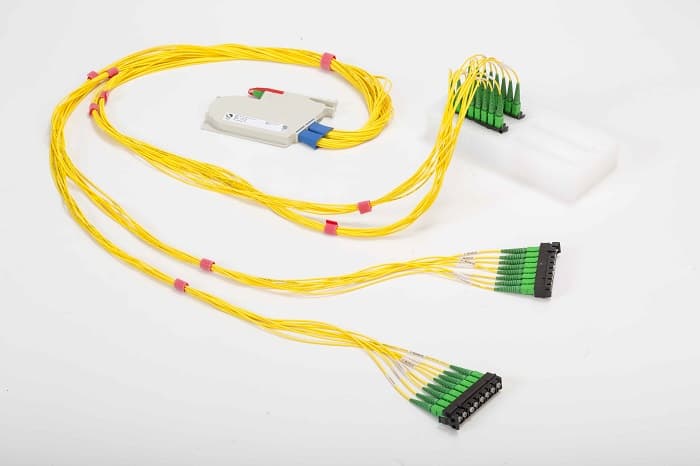

Fiber optic cable assembly with 33 fibers and terminations.

Further, the selection of connector types runs in the hundreds of styles and models. Generally, the selection for customization includes various choices of covers, housings, pins, and contacts.

Add other cable assembly components to the above list, which may be needed for a harness or assembly, such as:

- Ferrules

- Strain reliefs

- Shrink tubing

- Terminal blocks

- Enclosures

- Boots

- Bushings

- Potting material

In addition to the many component variations and complexities, additional processing requirements can also make an assembly very complicated. Examples of additional processing for cable assemblies include:

- Splicing

- Overmolding of the connectors, strain reliefs or transition areas

- Adding sleeves, braiding, or convolute for the protection of the cable harness assembly

Consequently, if you look at the number of variations possible to create an assembly, they are astounding! A complex cable assembly or custom cable harness would include a number of these various components, cable types, and additional processing into one assembly with many branches.

Sample Complex Cable Assemblies

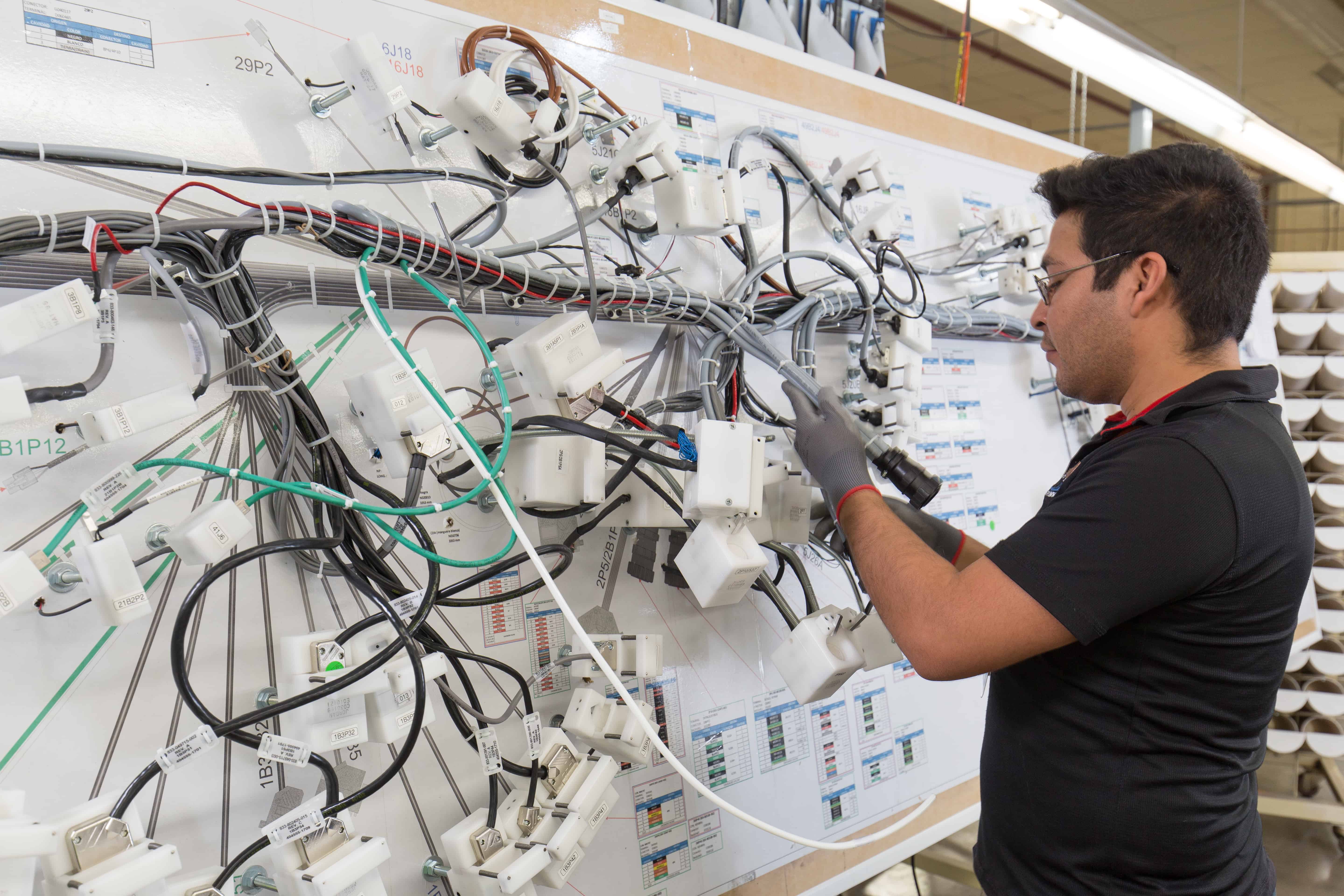

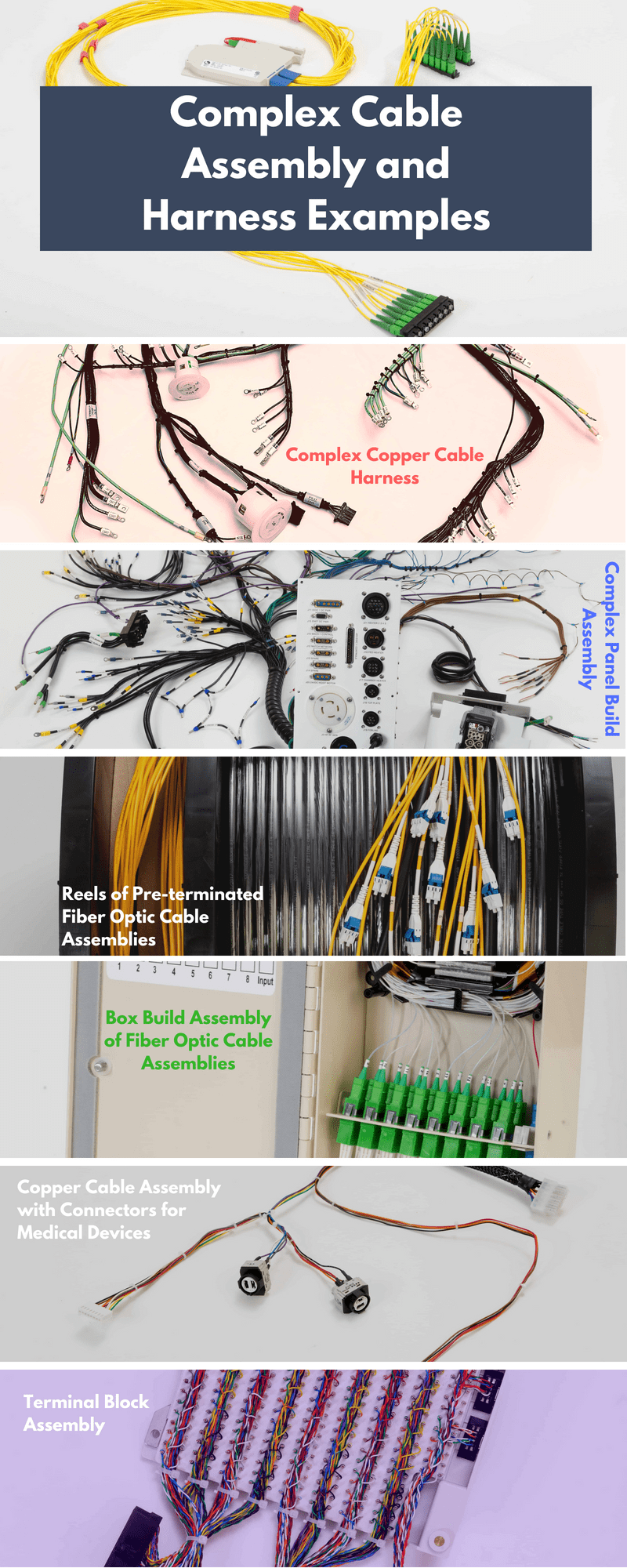

Complex cable assemblies and harnesses can include many branches and assemblies all bound together. This secures them for easier installation and protects them against the adverse effects of vibration, abrasion, moisture, or other harsh environmental conditions.

Here are a few samples of some complex and custom harnesses or assemblies:

Industries that Rely on Complex Cable Assemblies & Harnesses

Complex cable assemblies and harnesses play a vital role in a diverse range of industries, enabling the seamless transmission of power, data, and signals in complex and demanding applications. Among these industries, telecommunications, medical, and industrial sectors stand out as heavily reliant users of these intricate interconnect solutions.

Complex Cable Assembly Use in Telecom

In the telecommunications industry, complex cable assemblies are the backbone of communication networks, both wired and wireless. Complex cable harnesses and assemblies are instrumental in connecting cell towers, data centers, and optical fiber networks, ensuring the swift and reliable transmission of voice and data. These complex cable assemblies must be highly engineered to withstand harsh environmental conditions, electromagnetic interference, and provide efficient signal integrity.

For any telecommunications cable assembly applications NAI stands out as a trusted, experienced cable harness manufacturing partner.

Medical Innovations Rely on Complex Cable Harnesses & Cable Assemblies

In the medical sector, precision and reliability are of utmost importance. Complex medical cable assemblies and harnesses are integral components of medical devices, diagnostic equipment, and surgical tools. They facilitate critical functions such as patient monitoring, diagnostic imaging, and minimally invasive procedures.

These medical cable assemblies need to be carefully designed to meet stringent safety and regulatory standards, as well as ensuring biocompatibility in some cases.

Use of Complex Cable Assemblies and Cable Harness in Industrial Sectors

In the industrial sector, complex cable assemblies serve various purposes, from automation and robotics to manufacturing processes and control systems. They are employed in applications such as automotive assembly lines, industrial machinery, and factory automation. These industrial cable harnesses are designed to endure harsh industrial environments, with features like resistance to vibration, extreme temperatures, and chemical exposure, ensuring uninterrupted operations and worker safety.

These industries rely on complex cable assemblies and harnesses to maintain the efficient operation of their critical systems, making them indispensable components for modern technology and manufacturing. The customization and precision required for each industry further emphasize the importance of tailored cable solutions to meet specific needs and standards.

Find the Right Complex Cable Assembly Supplier

Choosing the right complex cable assembly supplier will be a critical decision in beginning the process of manufacturing complex custom cable assembly constructions. Here are a few tips to choose the best cable assembly manufacturer:

- Look at the depth and breadth of their custom cable assembly operations.

- Have they made similar types of constructions to those you are seeking?

- How well do they protect the assemblies as they progress through production lines?

- Verify their sourcing capabilities. With the hundreds and thousands of component variations and alternatives, your supplier must have established global sourcing networks to be able to quickly procure the parts needed. You want to select a manufacturing partner with a reliable global footprint.

- Talk to their Engineering department. Make sure they have the bench strength, experience, and capabilities needed to design the complex construction you require. Look at how they first begin working on a new project – what steps do they take? How long does it take to receive the First Article?

- Inspect their Quality Management System very carefully. Conduct an on-site examination of their quality checks for both fiber optic and copper assemblies.

- Also, look at the source’s shipping operations.

- Do they protect the product adequately for shipping?

- What shipping methods are available?

Follow these guidelines in selecting your complex cable assembly provider to ensure you receive the right product. Get what you need on time and meet all performance specifications without unwanted issues.

If you have any additional questions feel free to ask an expert who will be happy to answer any questions that you have.