Today, NAI operates five plants worldwide with nearly 500,000 sq. ft. of production capacity. Our current production levels are above 2.5 million assemblies, with over 25 million terminations per month and growing. While we employ over 2,000 personnel, hiring and training are ongoing at NAI.

-

NAI Manufacturing

In fact, one of the main advantages of working with NAI is our agility to ramp up quickly for any increase in demand – a learned capability from handling thousands of custom orders over many years.

We maintain a division of specialization at various plants and manufacturing cells to accommodate both High Mix / Low Volume orders, as well as High Volume / Low Mix orders. As a result, our ability to meet varying needs, along with our delivery performance, is second to none.

How NAI Can Leverage Its Global Footprint to Mitigate Your Production Risks

NAI’s global footprint provides a definite advantage for interconnect customers looking for extra insurance and to mitigate risk, so they can remain focused on providing continuity of supply to their customers. Read about how NAI helped one customer by building dual capacity in a different global location to help that customer maintain its product deliveries during the Coronavirus pandemic.

Read the Problem / Solution Story

Download the Problem / Solution Story

Responsive, Fast & Competitive

NAI aspires to continuously improve and reduce its overall cycle and response times. Whether for quoting, which is already considered to be very fast by our customers, or for manufacturing and delivery, NAI will continue to strive for improvement..

A Visual Story with Some of NAI’s Manufacturing Capabilities & Processes

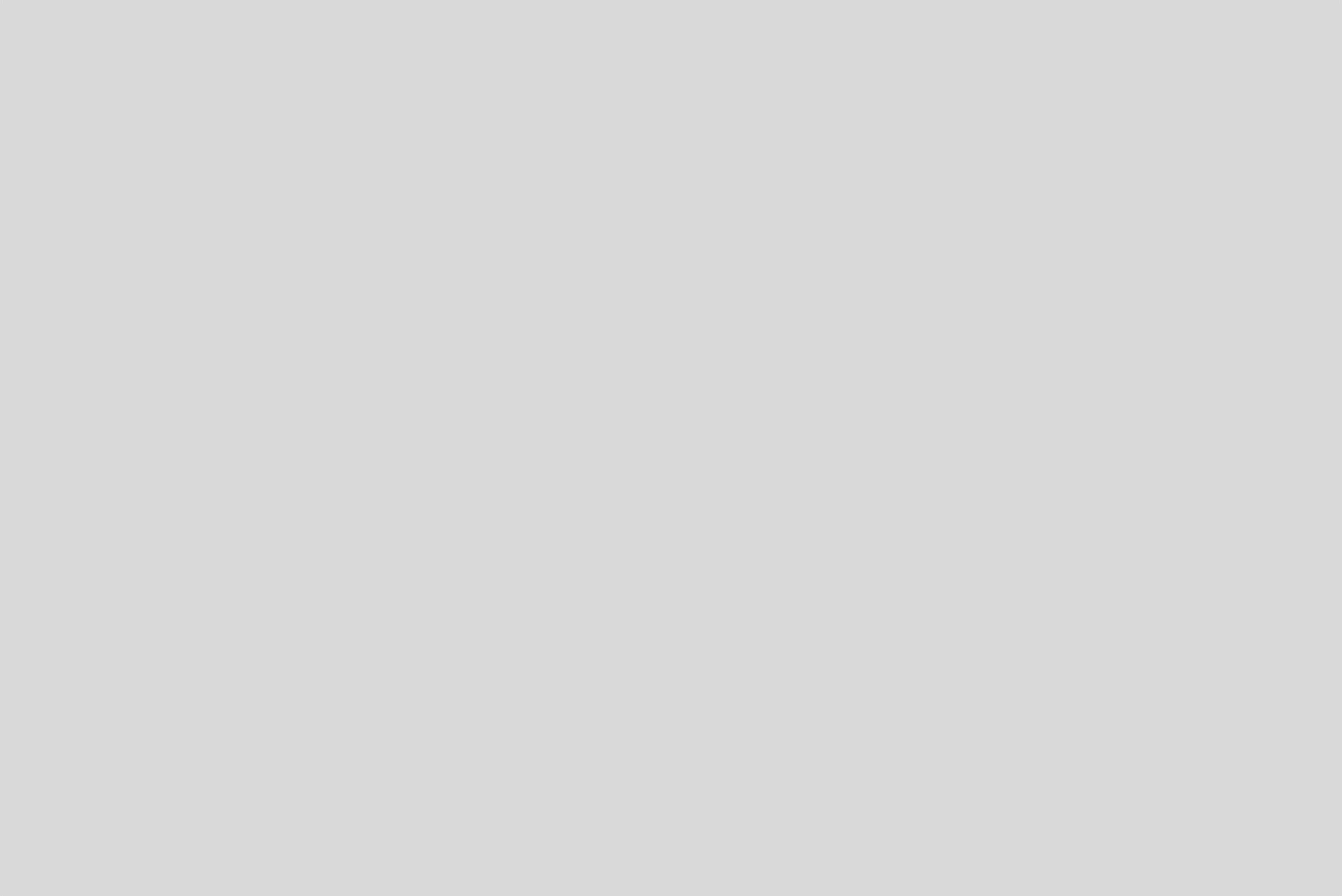

Assembly operation, dedicated to specific projects.

Ultrasonic welding station in a Clean Room.

Over-molding line of 16 machines for SPO2 assemblies.

Test Station in a Clean Room.

Separation and cleaning of fibers.

Epoxy is added and oven-hardened.

Connectors are added.

Automated equipment provides manufacturing efficiencies.

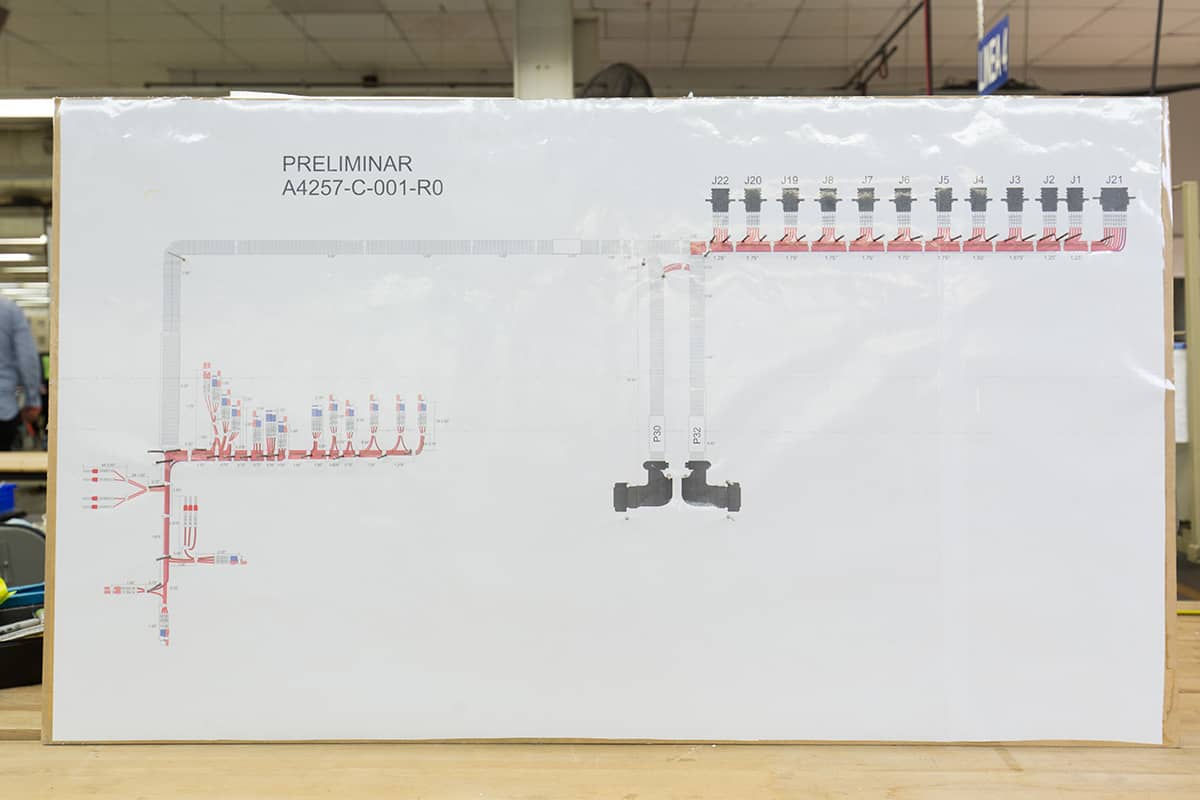

A visual representation of the cable assembly is created and used to guide manufacturing.

Various components are assembled to the cable on the line.

Automated equipment is used to polish fiber ends.

Test station for inspecting the end face of the fiber.

Potting operation with ovens.

One of many electrical tests are performed.

Final inspection of assembly with terminal block.

Watch this brief video of the automated Horizontal Injection Molding Equipment in NAI’s Gaylord, MI plant.

NAI SPO2 Automated Equipment

Additional Manufacturing Capabilities

- Custom production control software

- Semi-controlled room environment (ISO 8 equivalent)

- Clean room operations (Suzhou)

- Programmable polishing process platform for fiber

- Transition tube designs for breakouts and fan-outs

- Vacuum epoxy degassing system

- Laminar flow booths

- Encircled flux test

- Automated epoxy dispensing systems

- Bonding of overmolds to cable jackets

- Custom designs for overmolding standard connectors

- Custom designs of unique connector solutions

- Overmolding of PCBA’s

- Using Polyethylene and standard injection molding equipment instead of hot melt and LPM equipment, significantly reducing tooling, capital, and labor costs

- Fiber Optic Connector/Cable Interface

- Bubble-Free Interface

- Residue-Free Barrel

- Multi-Color Laser Marking

- Processing of Very Small Gage Wires

- 40 to 50 gage applications

- NAI’s rapid prototype process utilizes machined or 3D printed masters to create cosmetic or fully functional prototype connectors and components. From individual components to complete interconnect systems – prototyping is a useful option for validating a product design before investing in final tooling.

- Integrated vision systems into our electrical test systems to check for perfect reverse conditions and component verifications

- Fiber optic testing includes Insertion Loss, Return Loss, and Interferometry (Radius, Apex Curvature)

- NAI maintains and manufactures within a 100K (ISO Class 8) clean room environment for certain medical products

Packaging with Care

NAI will utilize both standard and custom packaging materials to ensure our customers’ products are shipped safely and securely. A few examples include:

- Tubing used to protect terminations

- Styrofoam packing designs

- Custom reels

We also use packaging to protect assemblies as they progress through the stages of manufacturing. This extra step is just a sample of the care we give to our customers’ projects.