01 May CASE STUDY: Mining Company Outsources Custom Cable Assemblies For Mining Control Modules

Plagued by extreme temperatures and harsh environmental conditions, it can be incredibly difficult to maintain consistent connectivity between a drill rig and its control center. When a mining company reached out to NAI, they quickly needed a reliable, durable, and custom connectivity solution, including cable assemblies and box builds, that could withstand these rugged and harsh conditions and provide uninterrupted data transmission and power.

NAI Group designed and manufactured custom cable assemblies and box builds for this customer’s demanding applications to build the control centers for its mining operations. These units were specially designed to withstand the harsh environmental conditions of the mining site and maintain connectivity between the control center and mining operations.

This case study showcases NAI Group’s expertise in providing customized connectivity solutions for challenging environments, such as the mining industry, as well as why outsourcing to interconnect specialists make business sense.

Problem: Current Cable Assembly Couldn’t Combat Harsh External Environments

A mining control manufacturer in China had difficulty building cable harness assemblies and control modules internally. Their expertise was in designing and manufacturing mining control products, not interconnects, so their control center was not properly optimized.

The control center in a mining operation is a centralized location where the operation of the mining equipment is monitored and managed. The purpose of the control center is to ensure that the mining operation runs smoothly and efficiently, while also maintaining the safety of the workers and the equipment.

The control center typically includes a variety of equipment, such as computers, communication systems, monitoring sensors, and control panels. The equipment is used to collect and analyze data from the mining equipment, such as drilling rigs, conveyors, and crushers, and to make adjustments to the operation of the equipment as needed.

It is equipped with sensors and alarms that can detect and alert operators to potential hazards, such as high levels of dust, gas, or vibration. In the event of an emergency, such as a fire or an equipment failure, the control center can quickly alert workers and initiate emergency procedures to ensure their safety.

As you can easily see, the control center in a mining operation is a critical component of the entire mining operation. Because the mining company did not have expertise in interconnect manufacturing, both quality and delivery suffered and requirements were not met.

Solution: Outsource To Optimize Interconnect Solutions

The mining company outsourced to NAI, an expert in manufacturing rugged custom cable assemblies and box builds for harsh environments, such as extreme temperatures, shock and vibration, dust, water, and other environmental hazards to prevent contamination of connectors and cables.

The mining company outsourced to NAI, an expert in manufacturing rugged custom cable assemblies and box builds for harsh environments, such as extreme temperatures, shock and vibration, dust, water, and other environmental hazards to prevent contamination of connectors and cables.

By being built to withstand these harsh environmental conditions, NAI’s rugged custom cable assemblies and box builds provided reliable connectivity between mining equipment, such as drilling rigs, conveyors, sensors, and custom control panels. As a manufacturer of custom interconnect products, NAI uses high-quality materials that can withstand extreme temperatures, abrasion, impact, and chemical exposure which are common in the mining industry.

By using rugged custom cable harnesses and box builds from NAI, the mining industry can be assured their equipment and control systems will remain connected and operational, even in the most challenging environments. This can help to minimize downtime, increase efficiency, and improve safety for workers in the mining industry.

NAI’s rugged custom interconnect solutions also came with an added benefit: the mining company could now achieve a better total cost for these outsourced products. Outsourcing to a knowledgeable expert in manufacturing interconnect products allowed this mining operator to free up tremendous amounts of working capital that had previously been allocated toward engineering, scheduling, purchasing, production, and building inventory.

NAI Solves Interconnect Issues For Chinese Mining Operations: The Benefits of Outsourcing Manufacturing

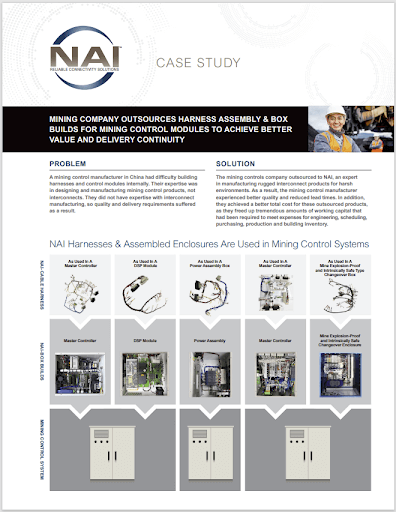

As a worldwide designer and manufacturer of custom cable assemblies and box builds, NAI assisted one of China’s leading mining control companies by producing custom rugged cable harness assemblies and custom box builds for various mining operations. Specifically, the interconnects and box builds were custom-assembled for different facets of control in the large-scale operational equipment used within the mines.

Phase 1: Implementation of 10 Different Custom Cable Harnesses Assembly Types

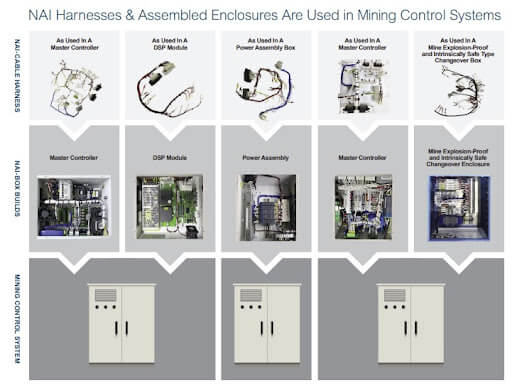

NAI manufacturing operations in Suzhou, China, recently began the project with the development and manufacture of very complex cable harnesses for installation within large explosion-proof enclosures. These cabinets are placed within mines for the operation and control of variable frequency drives and inverters.

NAI manufacturing operations in Suzhou, China, recently began the project with the development and manufacture of very complex cable harnesses for installation within large explosion-proof enclosures. These cabinets are placed within mines for the operation and control of variable frequency drives and inverters.

This equipment is crucial because it powers and controls conveyor belts, water and oil pumps, cooling fans, tape winding devices, and brakes inside the mines. In addition, they provide alerts and notifications for transformers, motors, cables, and other components when they are not operating within the expected temperature range, voltage range, or other parameters. All operational drives utilize NAI interconnect solutions for the transmission of control signals, which essentially serve as the nerve system for the mining operations.

The diverse cable harness assemblies were designed specifically for the control of variable frequency drives and inverters in mining applications. Ten different cable harness assembly versions were designed, each of which is used for data communications, control, and power. Harnesses carrying power were also included in the solution package. The typical data/control harness includes over 100 terminations, while the largest harness has more than 900 terminations. These custom cable harnesses have been designed to be very rugged and resilient in order to endure these demanding environmental conditions.

Phase 2: Custom Box Build Cable Assemblies House New Mining Interconnect System

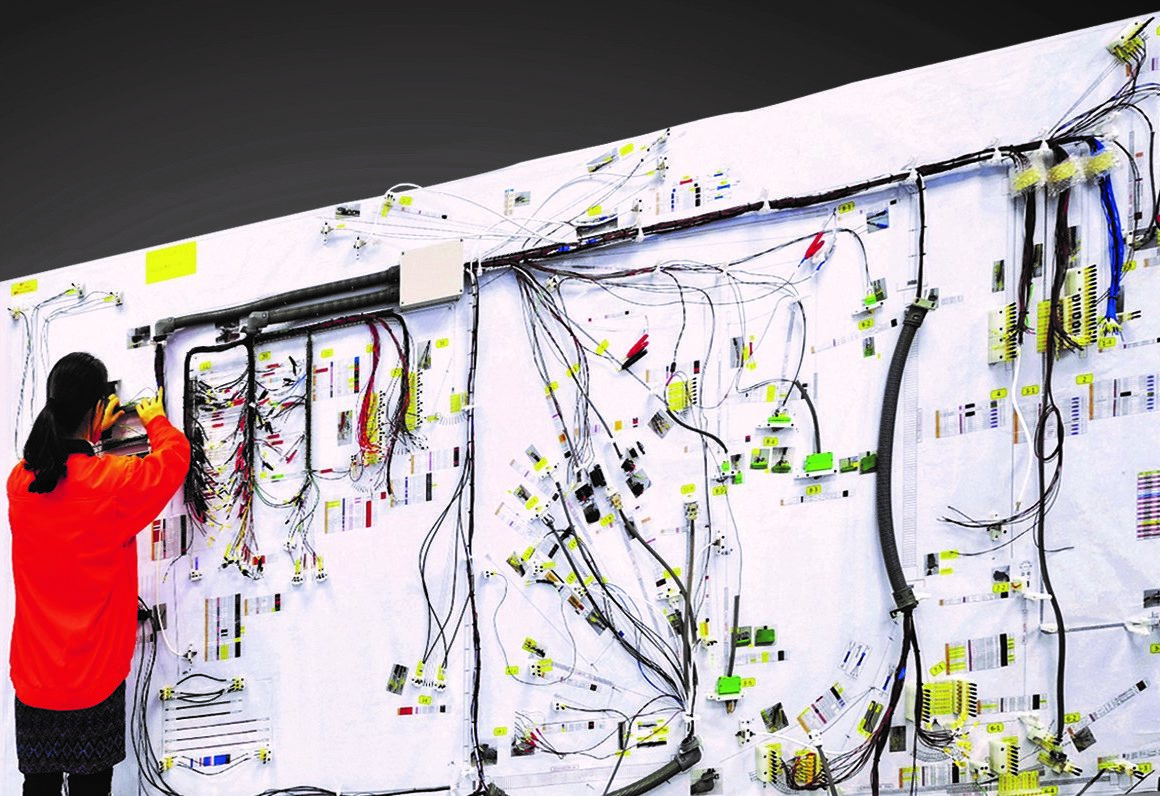

Sample box build for the mine control center.

The outsourcing of harnesses to NAI was very successful, so the customer began a second phase of development and manufacturing by having NAI produce a series of custom box builds. Each of these enclosures operates a different facet of a larger variable frequency drive and inverter system, and they are collectively installed within larger explosion-proof cabinets

NAI assembled five different industrial-grade enclosures to house the customer’s equipment for specific operations: a main controller for a high-voltage inverter, a DSP module, a power controller, the main controller for the inverter, and a control unit for intrinsic mine safety. Various complex harnesses were installed within these box builds, along with electronics and other components. The customer then installed these smaller enclosures into the larger cabinets to house the main control system, and these are placed within the mines.

In addition to providing a custom interconnect system, NAI made sure that the box build system was entirely up to code. All NAI products meet the requirements of the following mining tests, ratings, or standards:

- GB3836.2-2010 for explosive atmospheric conditions

- High voltage test at 330V for power cable

- Connectors are IP67 rated for resistance to dust and water

The customer for this mining project awarded the design and manufacturing of harnesses and box builds to NAI after their experience in producing these internally within their own manufacturing facilities was unsuccessful. After entrusting NAI to provide a massive custom cable assembly, this large-scale mining corporation was back on track and able to combat the harsh conditions of their industry successfully.

About NAI, A Leading Interconnect Solution Provider for Custom Cable Assemblies

With a massive global footprint, capital resources, design team, skill set, and industry knowledge, NAI designs and manufactures custom rugged cable assemblies, harnesses, and box builds for a variety of industrial applications.

From mining machinery to construction and agricultural equipment, robotics, machine tools, material handling equipment, and more, NAI is fully capable of providing numerous companies with the tools they need for their industry’s demanding requirements. Sign up for our newsletter to stay abreast of our latest solutions!

Our rigorous Quality Management Systems, along with the ability to make things happen very quickly, combine to make NAI a totally unique and attractive supplier for interconnect solutions in mining and beyond. Contact an NAI Expert today how they can provide custom cable solutions for you!