17 Oct What Are Fiber Optics Cable Assemblies Made of?

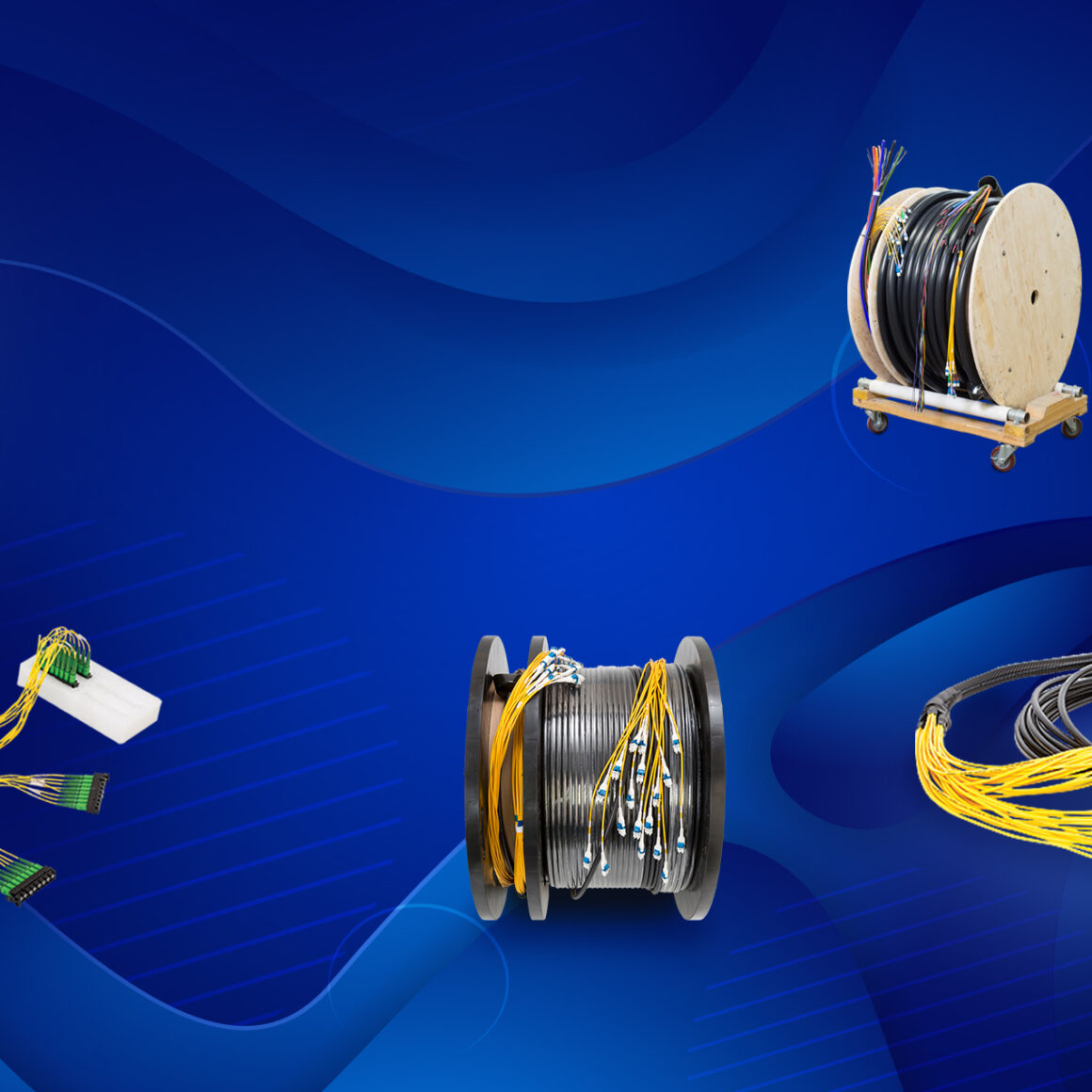

Telecom, data transfer, and the web are a few industries that fiber optic cables have transformed, but have you ever wondered how they’re made? As experts in the design and manufacture of fiber optic cable assemblies and fiber optic cable harnesses, NAI explains what fiber optic cable assemblies are made of and why they are important.

From home internet connections to industrial robots to the 27,000-km undersea network called the Fiberoptic Link Around the Globe (FLAG), fiber optic cables can be found in more places than we’d ever expected. Why are fiber optic cable assemblies so common? It’s because fiber optics have revolutionized countless industries with their superior signal transmission abilities. In addition, they have many desirable material properties.

The impressive performance of fiber optic cable assemblies and fiber optic cable harnesses is a result of the materials from which they’re made. Having relatively high mechanical strength given their hair-thin size, fiber optic cables are made from materials that can withstand harsh external conditions without compromising the important signals they carry.

Here is a deeper look at the materials that fiber optic cable assemblies are made of, the types of cable assemblies and harnesses you can choose from, and why it matters for your application.

What Are Fiber Optic Cable Assemblies Made Of?

Cable harnesses and assemblies are constructed by combining multiple cables and connectors to perform the desired function. When it comes to fiber optic cable assemblies and fiber optic cable harnesses, these products are created using fiber optic cables rather than copper cables. But what are these fiber optic components truly made of?

Cable harnesses and assemblies are constructed by combining multiple cables and connectors to perform the desired function. When it comes to fiber optic cable assemblies and fiber optic cable harnesses, these products are created using fiber optic cables rather than copper cables. But what are these fiber optic components truly made of?

The two most common materials for optical fibers are silica and plastic. When engineered correctly, both have impressive mechanical properties like flexibility and strength. They can also be designed with reflecting and refracting properties that are essential for signal transmission.

When it comes to creating a fiber optic cable assembly, the cost can be another deciding factor, but application and design may be the most important factors among the many fiber optic cable types available.

Is There Silica in Fiber Optics?

Typically, the thin filaments inside fiber optic cables are made from one of the most abundant materials on earth: silica. Short for silicon dioxide (SiO2), the fundamental material behind most fiber optic cables is the same compound found in sand.

Also used for solar photovoltaics and other electronics, the silica used for optical fiber is heated to extreme temperatures until it turns into glass. After further processing, the glass is heated and purified so that it becomes monocrystalline, which allows for minimal signal loss (attenuation). This purified glass is then slowly stretched until it forms thin filaments with the required diameter. The final product is a flexible optical fiber that — along with having a tensile strength of approximately 2 million psi — can withstand about 20 pounds of strain in a given fiber area.

Essentially, silica is transformed into a special glass to create the fiber optics we use in our cable assemblies and cable harnesses.

Is There Plastic in Fiber Optics?

One fiber optic technology trend is to use plastics instead of glass. Polymethyl methacrylate (PMMA) is the ingredient that makes up acrylic glass or plexiglass. It is also used to manufacture plastic optical fibers or POF.

It constitutes a 96% hybrid blend of materials to comprise the optical fiber core. While its exact material properties vary with its chemical composition, its cost-effectiveness often makes it favorable as a solution for consumer fiber optics products.

While plastic fiber is used for shorter distance runs and can typically be found in the home and in autos, glass fiber is used for longer distances and higher speeds, and can generally be found in commercial office and industrial applications.

How Are Fiber Optic Cable Assemblies Designed?

The decision to use glass or plastic as your optical fiber material may depend on the mode of transmission that applies to your cable assembly design and your end-use application. There are two different modes of fiber, which differ depending on how light travels through them:

- Single-mode Fiber Optics. Excluding their ability to relay a signal back and forth, single-mode fiber optic cables only refract the light signals they carry in one direction. Their small diameter of 9 micrometers allows them to control the mode of transmission tremendously. Additionally, single-mode cables are always made from glass.

- Multimode Fiber Optics. Having an average diameter of 125 microns, multimode optical fibers are larger than single mode and, thus, allow light to refract in multiple directions. Multimode fiber optic cables can be made from plastic or glass.

Another design parameter that may determine which material you use is the cladding type you need. Step index cladding has a single material composition throughout the fiber, while graded index cladding has multiple layers — each with a different refractive index. The result is a graded index that can steadily bend the light traveling through the fiber so that even less is lost during transmission. This, however, is more difficult to manufacture, making it more expensive.

Ultimately, it depends on the goals of your fiber optic cable harness or cable assembly to determine the makeup of the fiber optics. Knowing your end-use application, our NAI engineers can work with you to design a custom fiber optic cable assembly or harness to meet your exact specifications.

Design Custom Fiber Optic Cable Assemblies with Rich NAI Resources

NAI is here to help design your custom fiber optic cable assemblies or fiber optic cable harness. At NAI’s Solutions Center in Troy, Michigan, we have experienced design and application engineers who partner with our customers to provide the right connectivity solution for the application. Our capabilities can be scaled to meet our customers’ needs, ranging from design assistance to full service. Our NAI engineers are available to help our customers in selecting the appropriate off-the-shelf materials and perform VA/VE reviews of existing applications as well as design an entire fiber optic connectivity solution.

Support For Fiber Optic Technology at our NAI Center of Excellence

Through our expert NAI engineering and specialized testing, NAI’s dedicated Center of Excellence design and development facility ensures Design for Manufacturability (DFM), product performance, reliability, and on-time delivery and achieves cost savings for our partners. We also have proprietary processes for bonding over-molds to the cable jacket substrate and for near bubble-free fiber optic cable connections. Finally, we provide testing of all assemblies that we design to ensure they provide proper performance.

Through our expert NAI engineering and specialized testing, NAI’s dedicated Center of Excellence design and development facility ensures Design for Manufacturability (DFM), product performance, reliability, and on-time delivery and achieves cost savings for our partners. We also have proprietary processes for bonding over-molds to the cable jacket substrate and for near bubble-free fiber optic cable connections. Finally, we provide testing of all assemblies that we design to ensure they provide proper performance.

Learn more about fiber optics in our blogs, What Is Optical Fiber Technology and How Does It Work and What is the Future of Fiber Optics in Medicine?

Connect With The Leaders in Fiber Optics, NAI

NAI is at the forefront of engineering the fiber optic cable assembly solutions that connect the most innovative devices and equipment. Fiber optic cable assemblies are used by a host of industries as diverse as telecommunications, datacom, healthcare, and industrial technologies.

Therefore, we have extensive expertise with the various fiber cables that many sectors employ. We also leverage our integrated supply chain and global manufacturing footprint to ensure the delivery of the connectivity solutions our customers require. You can always keep up with our latest trends by signing up for the NAI newsletter.

Ask an Expert today to find the best fiber optic cable assemblies or harness solution for you.