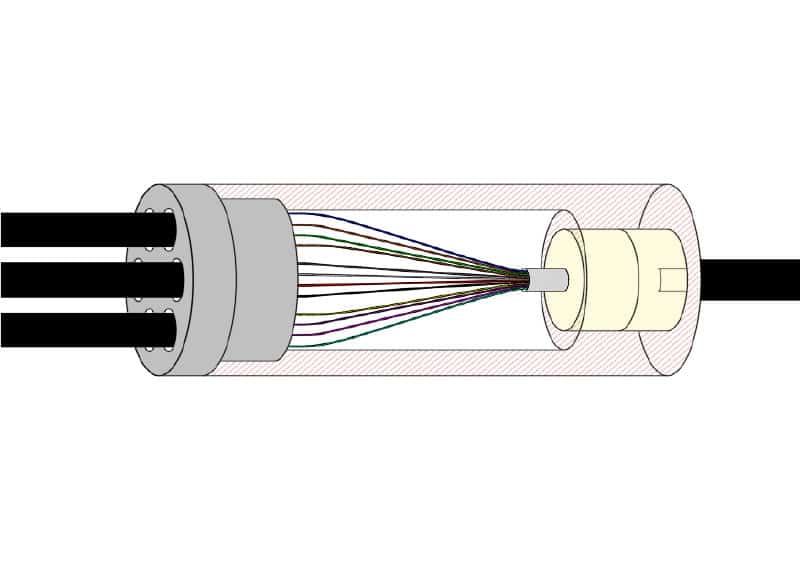

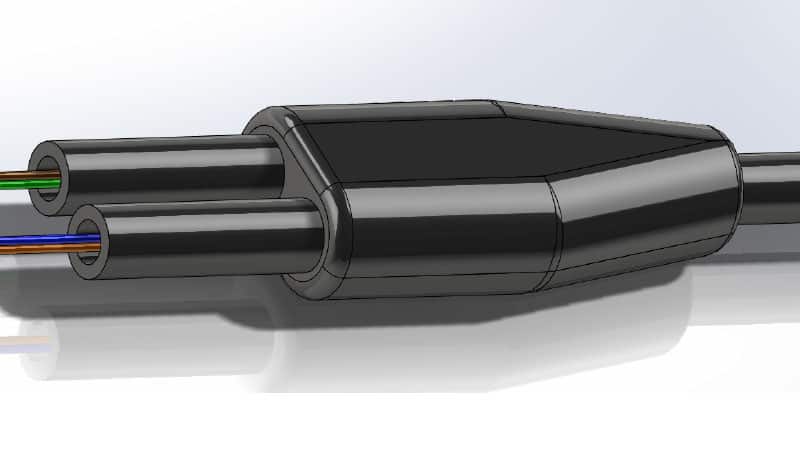

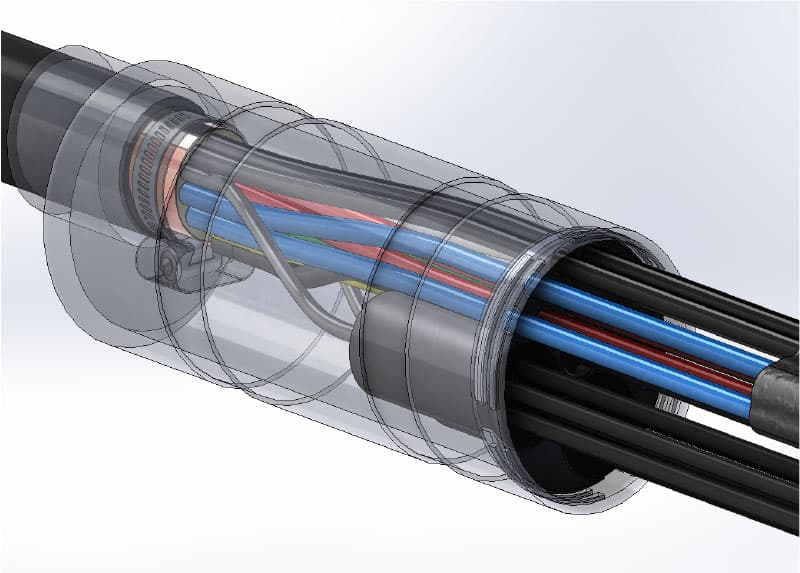

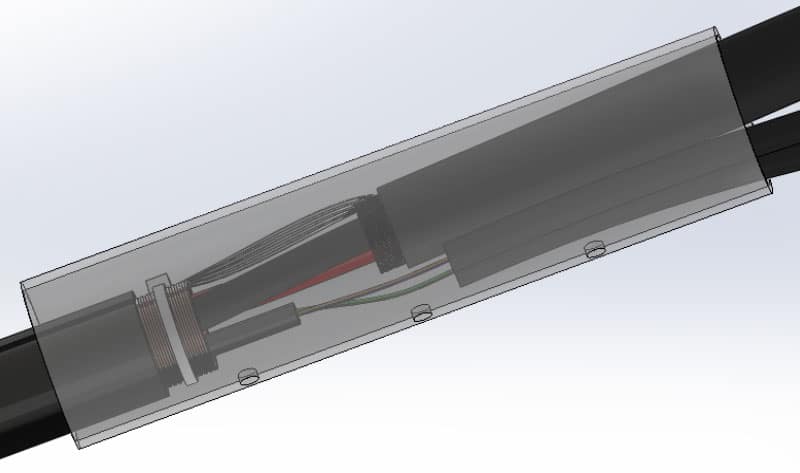

NAI utilizes a large variety of cables, connectors, blocks and other components in our manufacturing operations. Our Global Sourcing Team often procures alternative components that meet project specs and achieve overall cost savings. Here are just some of the components and materials used in typical assembly work: